Boiler Performance Testing

Boiler performance testing ensures the unit operates efficiently and safely. The primary objectives include evaluating thermal efficiency, fuel-to-steam ratio, and emission levels. Key parameters measured during testing include fuel consumption, steam output, feedwater temperature, and flue gas composition.

Testing involves the use of instruments to measure pressure, temperature, and flow rates at various points in the boiler system. Data collected helps in identifying areas for efficiency improvements and ensuring compliance with environmental regulations.

- Applicable ASME PTC Standards: ASME PTC 4 – Fired Steam Generators.

Waste Heat Recovery Boiler (WHRB) Performance Testing

WHRBs capture waste heat from industrial processes to generate steam, enhancing overall plant efficiency. Performance testing for WHRBs involves evaluating heat recovery effectiveness, steam generation rates, and exhaust gas temperature.

The process includes measuring the temperature and flow rate of exhaust gases entering the WHRB, steam output parameters, and comparing them to design specifications. Efficiency calculations are performed to assess the WHRB's ability to recover and utilize waste heat.

- Applicable ASME PTC Standards: ASME PTC 4.4 – Waste Heat Recovery Units.

Air Preheater (APH) Performance Testing

APHs improve boiler efficiency by preheating the combustion air using residual heat from flue gases. Performance testing of APHs focuses on assessing heat transfer efficiency, pressure drops, and temperature profiles.

Testing involves measuring inlet and outlet temperatures of air and flue gas streams, calculating heat recovery rates, and identifying any leakage between the air and gas sides. Proper functioning of APHs ensures optimal fuel combustion and reduced emissions.

- Applicable ASME PTC Standards : ASME PTC 4.3 – Air Heaters.

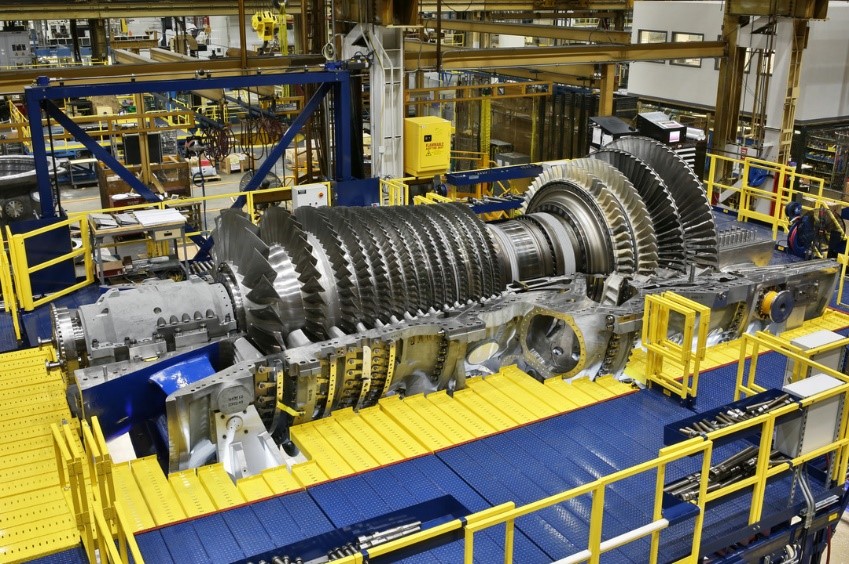

Turbine Performance Testing

Turbines convert thermal energy into mechanical energy, and performance testing ensures they operate at peak efficiency. The testing process includes measuring parameters such as steam pressure and temperature, turbine speed, and power output.

Analyzing these parameters helps in identifying any performance deviations, assessing turbine efficiency, and detecting potential mechanical issues. The goal is to optimize power generation and ensure reliable operation.

- Applicable ASME PTC Standards: ASME PTC 6 – Steam Turbines.

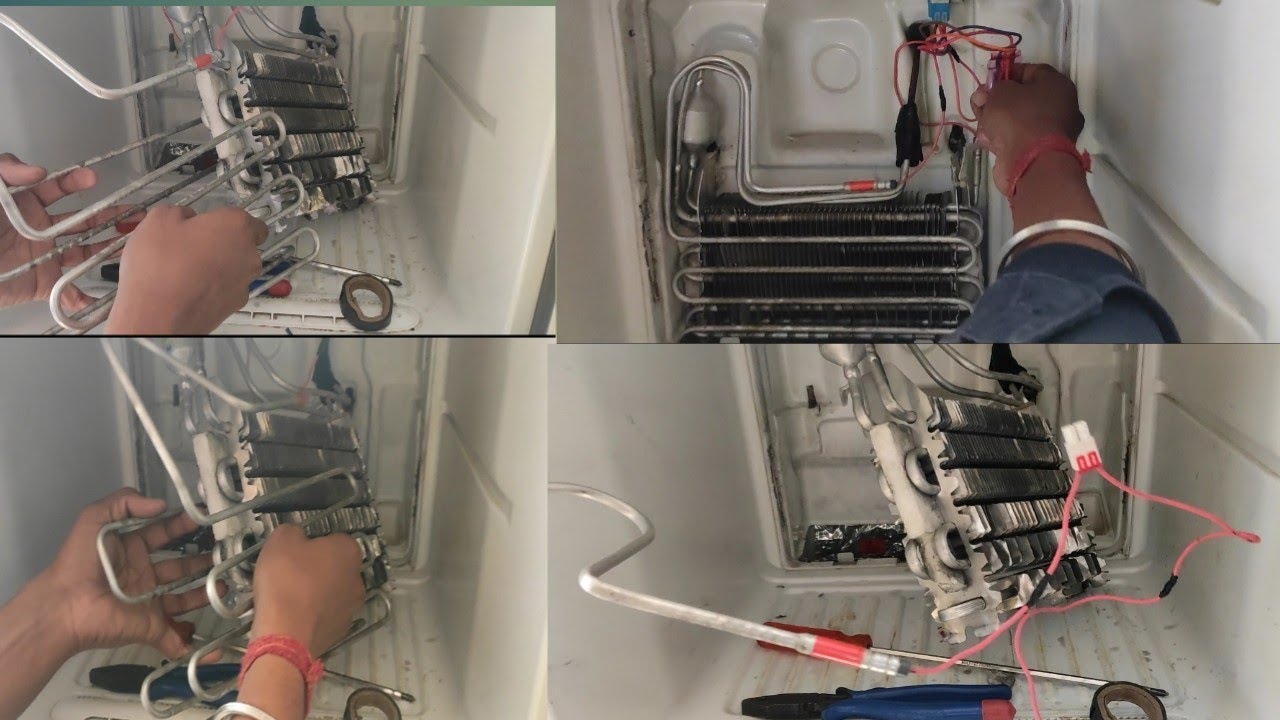

Heater Performance Testing

Heaters, including feedwater and superheaters, are critical for maintaining steam quality and efficiency. Performance testing of heaters involves measuring inlet and outlet temperatures, pressure drops, and heat transfer rates.

Testing helps in evaluating the effectiveness of heat transfer, identifying fouling or scaling issues, and ensuring heaters meet design specifications. Efficient heater operation is vital for overall plant performance and fuel efficiency.

- Applicable ASME PTC Standards : ASME PTC 12.1 – Closed Feedwater Heaters.

Cooling Tower Performance Testing

Cooling towers dissipate heat from the power plant to the atmosphere. Performance testing focuses on evaluating cooling efficiency, water evaporation rates, and thermal performance under various load conditions.

Measurements include inlet and outlet water temperatures, ambient air conditions, and water flow rates. Testing ensures the cooling tower can effectively maintain optimal temperatures for plant equipment, contributing to overall efficiency and reliability.

- Applicable ASME PTC Standards: ASME PTC 23 – Atmospheric Water Cooling Equipment.

Flue Gas Desulfurization (FGD) System Performance Testing

FGD systems reduce sulfur dioxide emissions from power plants. Performance testing evaluates the system's removal efficiency, reagent consumption, and byproduct quality.

Testing involves measuring the concentration of sulfur dioxide in flue gases before and after treatment, monitoring reagent flow rates, and assessing the quality of produced gypsum. Effective FGD operation ensures compliance with environmental regulations and reduces atmospheric pollution.

- Applicable ASME PTC Standards : ASME PTC 40 – Flue Gas Desulfurization Units.